- Home

- About Us

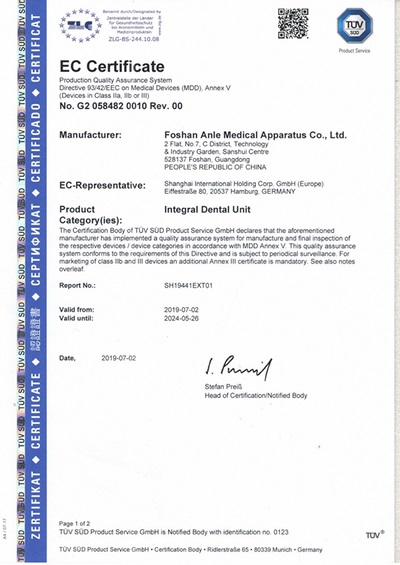

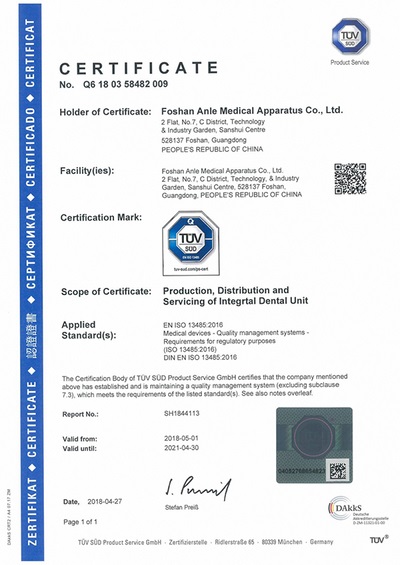

Foshan Anle Medical Apparatus Co., Ltd. is a class II dental equipment manufacturer founded in 1998 with our primary product are CE and TUV certified dental units.

With our own production facilities, we feature a monthly production capacity of more than 700 dental units. During production, we maintain strict control over all product quality factors and supervise the entire production process, ensuring only qualified materials are put into production, only qualified parts are transferred to the next process, and only qualified products leave our facilities. This ensures all dental units our customers receive not only meet industry standards, but exceed customer expectations.

After more than 2 decades of development and growth, our products have been exported to more than 70 countries and regions around the world, including Germany, Britain, Italy, Mexico, Chile, Argentina, India, the Middle East, Southeast Asia, and more.

It is our goal to continue working with international brand leaders and continue to develop partnerships with customers all over the world to assist in the development of the dental industry.

Backed by extensive experience, not only do we strictly control product quality, but we are also able to effectively control product production costs, ensuring the dental units are a perfect combination of quality and economy.

Raw materials

Raw material quality and processing technology are vital to product safety and effectiveness.

We sample raw materials for testing according to raw material inspection standards before they ever enter the warehouse. Only raw materials deemed qualified will be put into storage, while the rejected raw materials will be returned to the supplier.

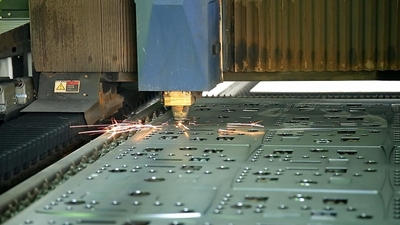

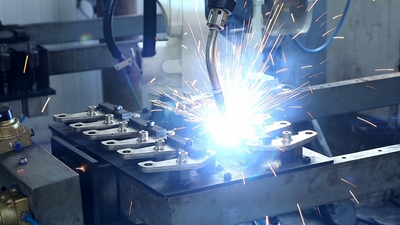

Production and Processing

Our factory has both a metal machining workshop and plastic machining workshop.

We also own and operate a full set of high precision processing equipment, including punching machines, bending machines, laser cutting machines, spot welding equipment, and injection molding machines. This equipment ensures our independent production, high efficiency and exceptional product quality.

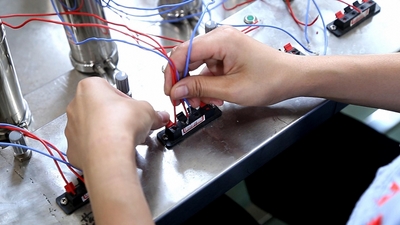

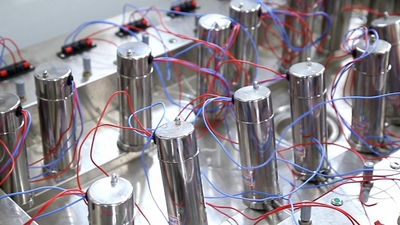

Assembly and Inspection

We have established strict assembly standards, and have set up several semi-finished product assembly lines, two finished product assembly lines, and a designated quality inspection area.

Semi-finished products are first assembled on the semi-finished product assembly lines before they are sent to the finished product assembly line for final product assembly. The finished dental unit will then be sent to the quality inspection area for a quality inspection process.

Our quality inspectors inspect products in regards to appearance, function, safety and stability according to related international standards to ensure final product qualification.